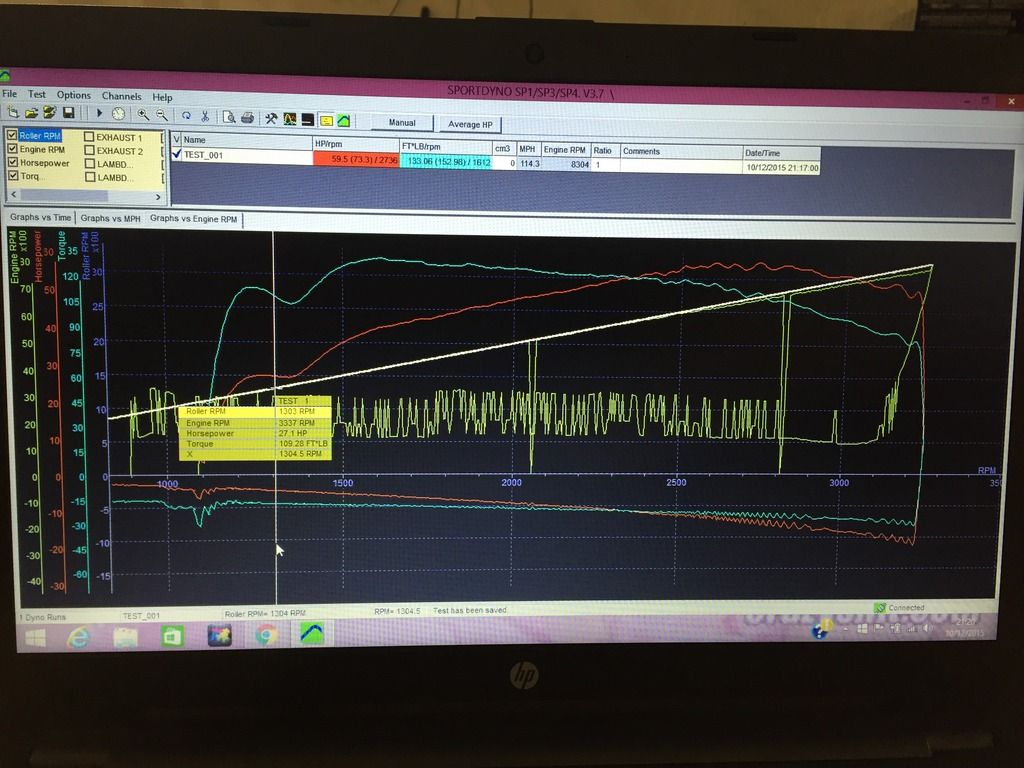

I asked on the XR650 forum on thumpertalk what the hp of a XR is, answer came back 43 stock, 48 uncorked, both flywheel figures so my readings are way off. Anyhoo, I spoke with the sport devices agent and he suggested it was a option in the setup menu. So I had a look at it yesterday.

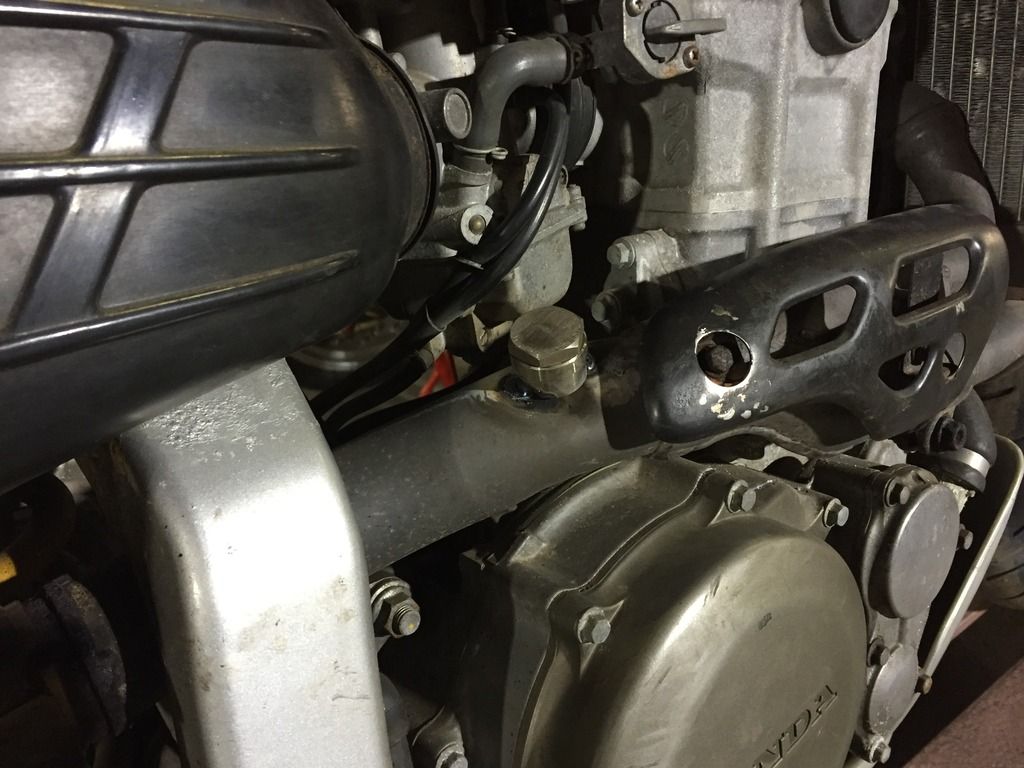

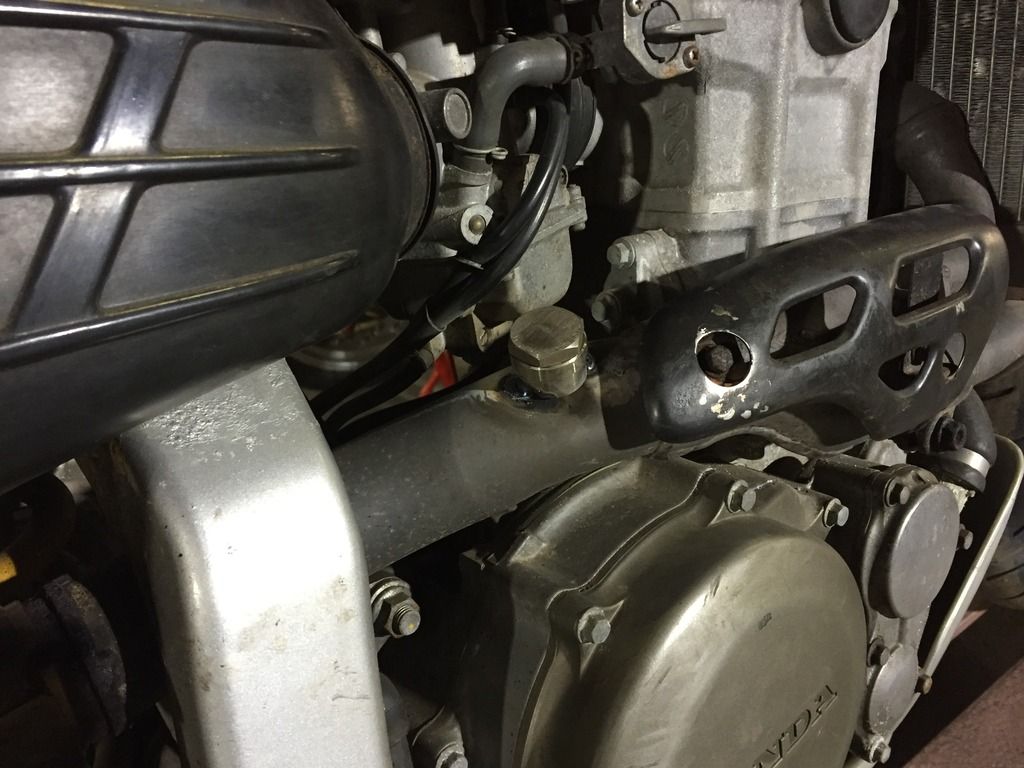

I thought I would quickly hook up the A/F ratio gauge (lambda) of the turbo bike. So I drilled a hole in the header and spotted on a sensor bung, the dyno interface has a particular kind of plug at the back for taking 0-5v feeds from sensors and the AEM A/F gauge has a 0-5v output, it's called a microphone plug or a aviation plug on some sites.

The anti climax to this is, I had ordered some plugs, but the one I needed had been wrongly supplied. In addition to this I had ordered a k type thermocouple plug but it was wrong also when it came but that was my mistake. So I could have had both that sampled but no, it was not to be. I have re-ordered plugs and at least some of the legwork has been done in that direction.

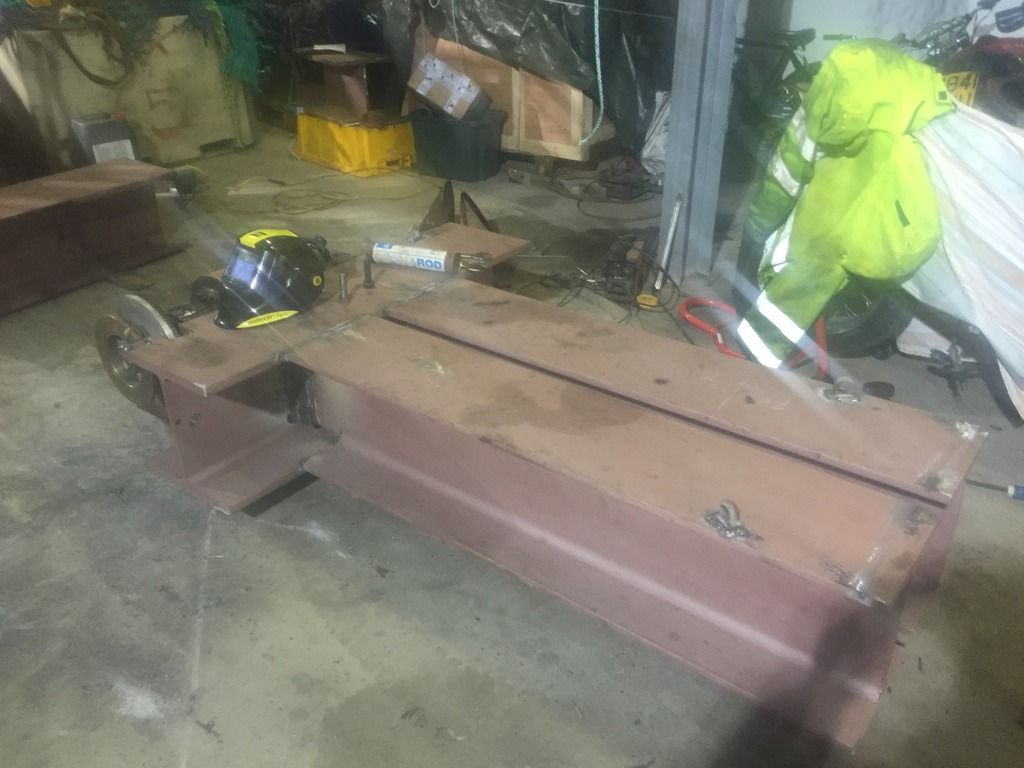

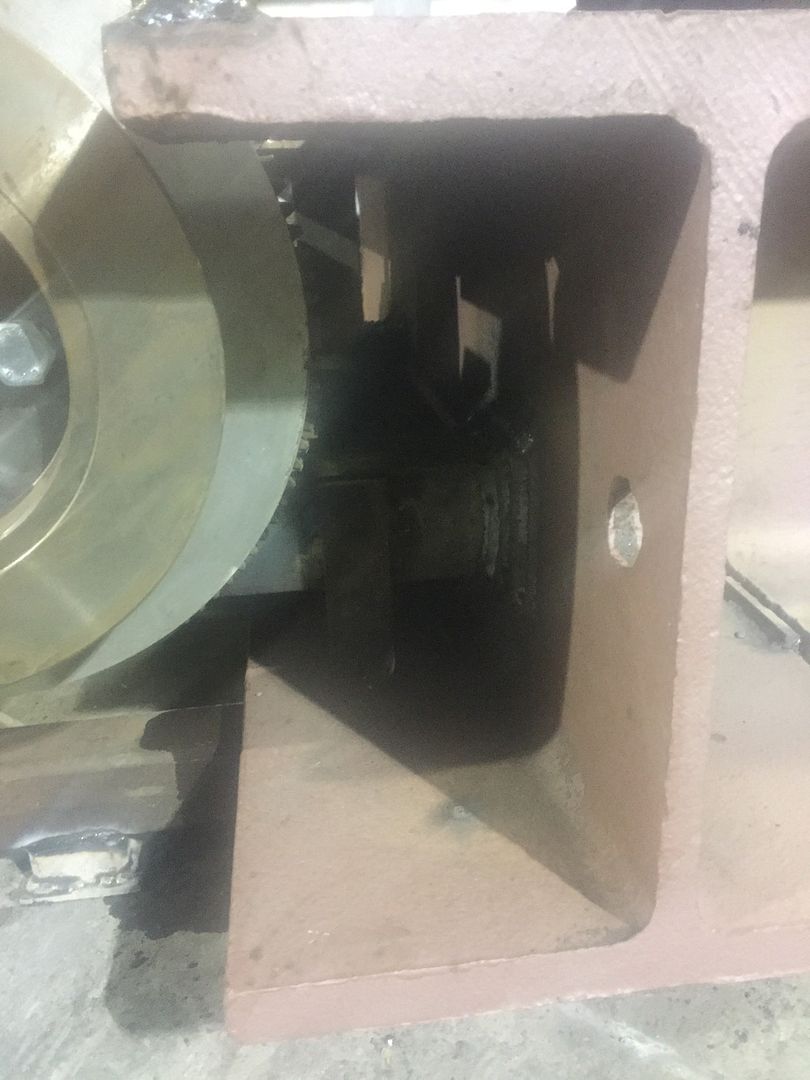

So I did a few runs but with similar results to before. So it was not that option that was the root of it. It's quite good fun running the bike on the roller. It's almost like sitting on something living. The bike sure does get hot quick, I have been gathering bits to solve that. I have a 550mm diameter fan that is off a refrigeration unit of some kind, that's for the cooling of the bike and a squirrel cage blower off a steam cleaner of about 150mm for the exhaust extraction, both bought off eBay for a few pounds as new old stock. I am thinking to mount them on a common shaft driven by a 3 or 4hp single phase motor.

I spoke to the sport devices agent for a bit afterwards and he asked me all the things I had done. Think he has sorted it, the calibration thing where you run up the bike slowly on part throttle to a chosen rpm so there is no slippage and it then figures out the rpm ratio between the engine and the roller(the interface box has a rpm pickup that you clip to the plug wire), when I did this I assumed the dyno used this ratio itself, but no, I have to manually enter that value on another window. It makes most sense, I will try that next week when I get finished with work for Christmas.

Just as a BTW, the interface box senses the power of the bolt going through the plug wire but it knows when the engine is on the ignition stroke because with the high cylinder pressure it is a stronger spark, then on the next revolution the engine is exhausting as the spark plug fires but the interface box know not to count that one as its a weaker bolt because of the low cylinder pressure. Now that's a bit clever. There is a option to select for when you are running up a two stroke so no worries Mike.