Building your own Dyno

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Building your own Dyno

So you think you made some cool mod on your scoot.

You take it out and run it down the road and the butt dyno say's "YEAH!!!!!"

But often times the butt dyno is extremely inaccurate.

So, lets examine building your own Dyno

What?

Sound scary?

Perhaps not as much as you might first think.

What does a dyno measure?

Work.

So imagine a big fly wheel with a known weight and diameter being driven and measuring how fast you can speed up that flywheel...

Here is one fellas example:

https://www.youtube.com/watch?v=ZQNVKyNYyIA

You take it out and run it down the road and the butt dyno say's "YEAH!!!!!"

But often times the butt dyno is extremely inaccurate.

So, lets examine building your own Dyno

What?

Sound scary?

Perhaps not as much as you might first think.

What does a dyno measure?

Work.

So imagine a big fly wheel with a known weight and diameter being driven and measuring how fast you can speed up that flywheel...

Here is one fellas example:

https://www.youtube.com/watch?v=ZQNVKyNYyIA

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

Of course you could incorporate things like your engine RPM, Exhaust Gas temps, Water temps ect.

So let's start with the basics.

A steel frame, a heavy flywheel on pillow blocks, a way to strap your scoot down, a trigger for measuring the flywheel speed, engine rpm, and how to capture that data on your lap top.

And how about some ventilation

So let's start with the basics.

A steel frame, a heavy flywheel on pillow blocks, a way to strap your scoot down, a trigger for measuring the flywheel speed, engine rpm, and how to capture that data on your lap top.

And how about some ventilation

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

Oh... and some safety gear...

Fire extinguisher, ear protection, decking to cover most of the flywheel.... What else???

Fire extinguisher, ear protection, decking to cover most of the flywheel.... What else???

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

Interesting site.

I will be looking at it closely later today...

http://www.land-and-sea.com/do-it-yours ... -plans.htm

I will be looking at it closely later today...

http://www.land-and-sea.com/do-it-yours ... -plans.htm

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

tobys 2 strokes

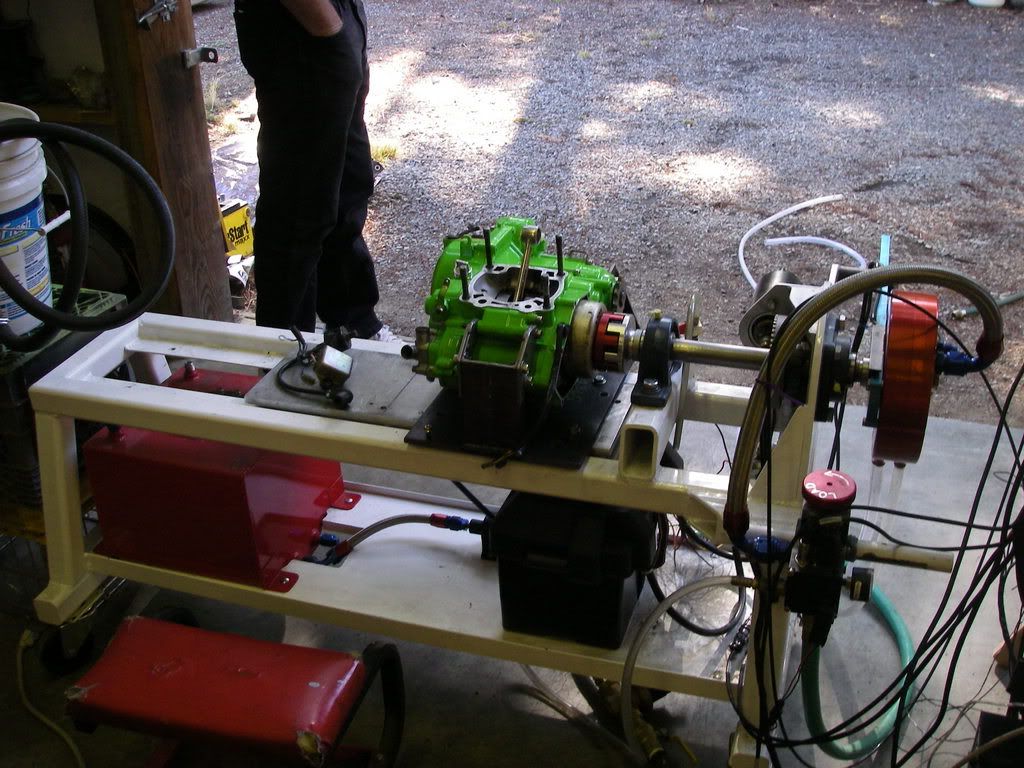

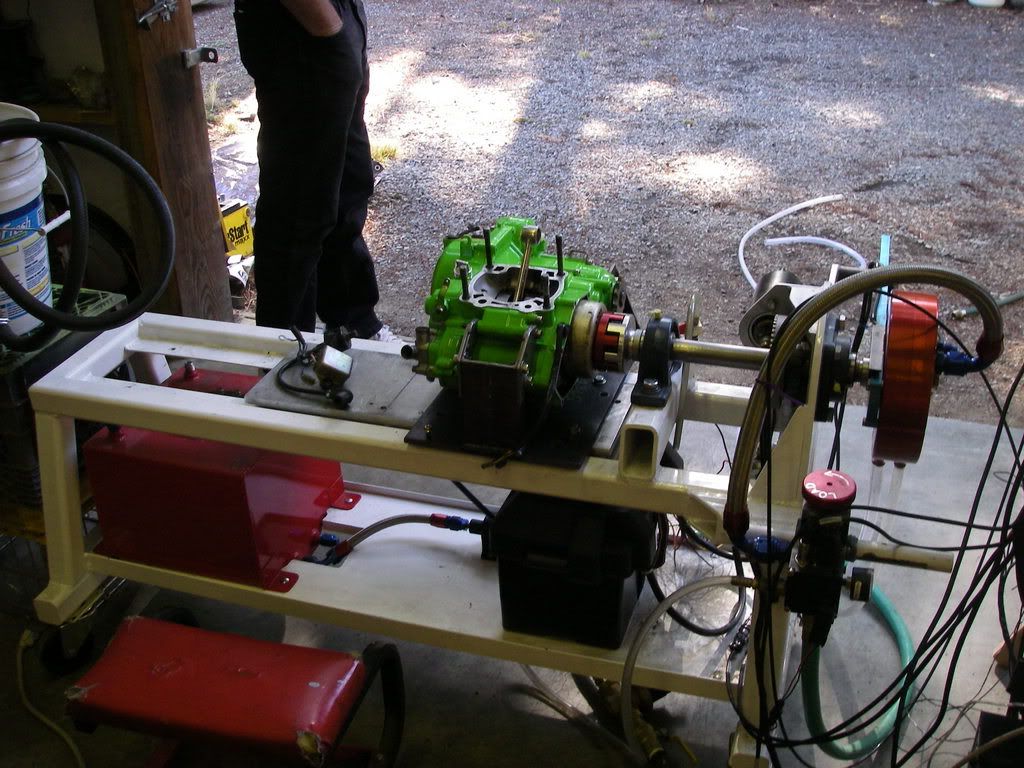

I got to spend a day in Dave Roberts shop (ILR performance) with my tecate 330 on his Dyno. its a Land and Sea dyno.

it measures it at the crank.

I think you could make somthing simular with a hyd pump and valves and pressure sensors

I got to spend a day in Dave Roberts shop (ILR performance) with my tecate 330 on his Dyno. its a Land and Sea dyno.

it measures it at the crank.

I think you could make somthing simular with a hyd pump and valves and pressure sensors

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

That's cool.

What kind of results did you get?

For me, (Cause I'm simple) I'd rather measure at the rear wheel for a couple of reasons.

I don't want to pull my engine every time I want to do a dyno run.

Something as simple as a different chain and sprocket set will change effect your rear wheel HP.

And it seems like it would be difficult to calibrate and maintain calibration of the fluid type dyno's.

I need simple.....

But let's discuss it...

What kind of results did you get?

For me, (Cause I'm simple) I'd rather measure at the rear wheel for a couple of reasons.

I don't want to pull my engine every time I want to do a dyno run.

Something as simple as a different chain and sprocket set will change effect your rear wheel HP.

And it seems like it would be difficult to calibrate and maintain calibration of the fluid type dyno's.

I need simple.....

But let's discuss it...

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

Dutch-K5 Fan

Whant one for my sellf like so many things

http://www.hpi.be/dyno.php

Maybe this could work?

Dutchie

Whant one for my sellf like so many things

http://www.hpi.be/dyno.php

Maybe this could work?

Dutchie

If bikes are for kids I'll never grow up.

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

Thanks for the link Dutchie...

You should buy it and let us know how it works

You should buy it and let us know how it works

If bikes are for kids I'll never grow up.

- Crofter985

- Posts: 240

- Joined: Mon Nov 10, 2014 6:47 pm

- Location: Shetland Islands, UK

Re: Building your own Dyno

This is the Australian web page I mentioned in the other thread.

http://dtec.net.au/index.htm

For a 1000 bucks Australian you get the hardware and software just supply your own flywheel

http://dtec.net.au/index.htm

For a 1000 bucks Australian you get the hardware and software just supply your own flywheel

- Sandblaster

- Posts: 6318

- Joined: Thu Jun 07, 2012 3:50 pm

- Location: Eugene, OR

- Contact:

Re: Building your own Dyno

1901306708

the land and seas are allright. the strain sensor failed often on the one i was around.

what works good is if you take the power off your front sprocket. take an old sprocket and weld a ~4 in long piece of pipe onto it. use a large enough ID to get your snap ring pliers inside to attach it to your bike. on the other end of the piece of pipe, weld on a flange. weld the same flange onto a shaft going to your dyno and bob's your uncle. its nice to have a rubber dampnner in your system somewhere.

power varies alot with air temp, crankcase temp, coolant temp all sorts of things so consistancy is important.

the land and seas are allright. the strain sensor failed often on the one i was around.

what works good is if you take the power off your front sprocket. take an old sprocket and weld a ~4 in long piece of pipe onto it. use a large enough ID to get your snap ring pliers inside to attach it to your bike. on the other end of the piece of pipe, weld on a flange. weld the same flange onto a shaft going to your dyno and bob's your uncle. its nice to have a rubber dampnner in your system somewhere.

power varies alot with air temp, crankcase temp, coolant temp all sorts of things so consistancy is important.

If bikes are for kids I'll never grow up.

Who is online

Users browsing this forum: No registered users and 26 guests